MIRLE Energy Saving System for Injection Molding Machines (IMM)

MIRLE offers advanced energy-saving solutions for Injection Molding Machines (IMMs), designed to reduce power consumption, enhance efficiency, and lower operational costs. The system integrates servo-driven technology, intelligent power management, and real-time monitoring to optimize energy use while maintaining high-performance molding operations.

Key Features of MIRLE Energy Saving System:

1. Servo Motor-Based Energy Efficiency

Utilizes high-efficiency servo motors instead of traditional hydraulic pumps.

Reduces energy consumption by up to 50%, ensuring lower electricity costs.

Delivers fast response time with precise control over pressure and flow.

2. Intelligent Power Management

Dynamically adjusts power usage based on machine load and operational requirements.

Minimizes energy waste during idle periods.

Ensures consistent and stable pressure, reducing variations in molded products.

3. Real-Time Monitoring & Smart Control

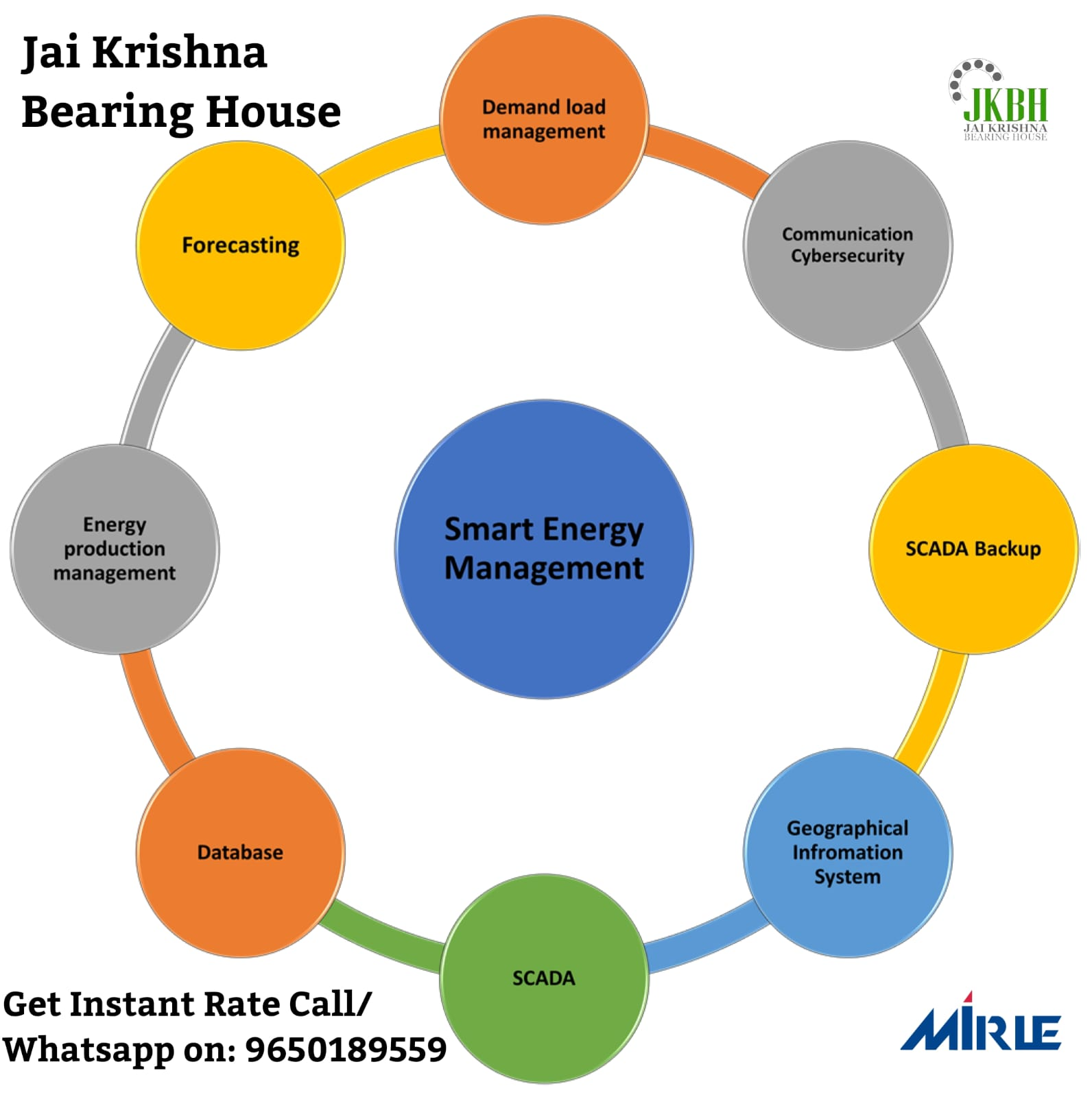

Integrated with SCADA, IoT, and smart factory automation systems.

Provides real-time data tracking, enabling predictive maintenance and efficiency analysis.

Users can monitor energy savings and system performance remotely.

4. Reduced Heat Generation & Extended Machine Life

Lowers heat buildup, reducing the need for additional cooling systems.

Minimizes wear and tear on components, extending the lifespan of IMMs.

Improves overall productivity with fewer maintenance requirements.

5. Eco-Friendly & Cost-Effective Solution

Supports sustainable manufacturing by reducing carbon footprint.

Meets global energy efficiency standards for industrial automation.

Provides faster ROI through significant electricity savings.

Applications of MIRLE Energy Saving System:

✅ Plastic Injection Molding Machines – Reduces hydraulic energy loss and increases production efficiency.

✅ Hydraulic & Pneumatic Systems – Optimizes fluid pressure and flow for reduced energy consumption.

✅ Manufacturing & Automation – Integrates with robotic arms, conveyors, and other machinery.

✅ Automotive & Electronics Industries – Helps optimize precision molding with energy savings.

Why Choose MIRLE Energy Saving Solutions?

✔ Up to 50% Power Savings

✔ Intelligent Adaptive Control

✔ Improved Product Quality & Consistency

✔ Lower Operational & Maintenance Costs

✔ Eco-Friendly & Industry 4.0-Ready

MIRLE’s Energy Saving System for Injection Molding Machines ensures high efficiency, precision, and sustainability, making it the ideal choice for modern manufacturing facilities.

Keywords

ideal choice

sustainability making

faster roi

industrial automation

imms improves

components extending

scada iot

machine load

precise control

realtime monitoring

optimize energy

energy savings

monitor energy savings

modern manufacturing facilities

robotic arms conveyors

efficiency analysis users

lower operational costs