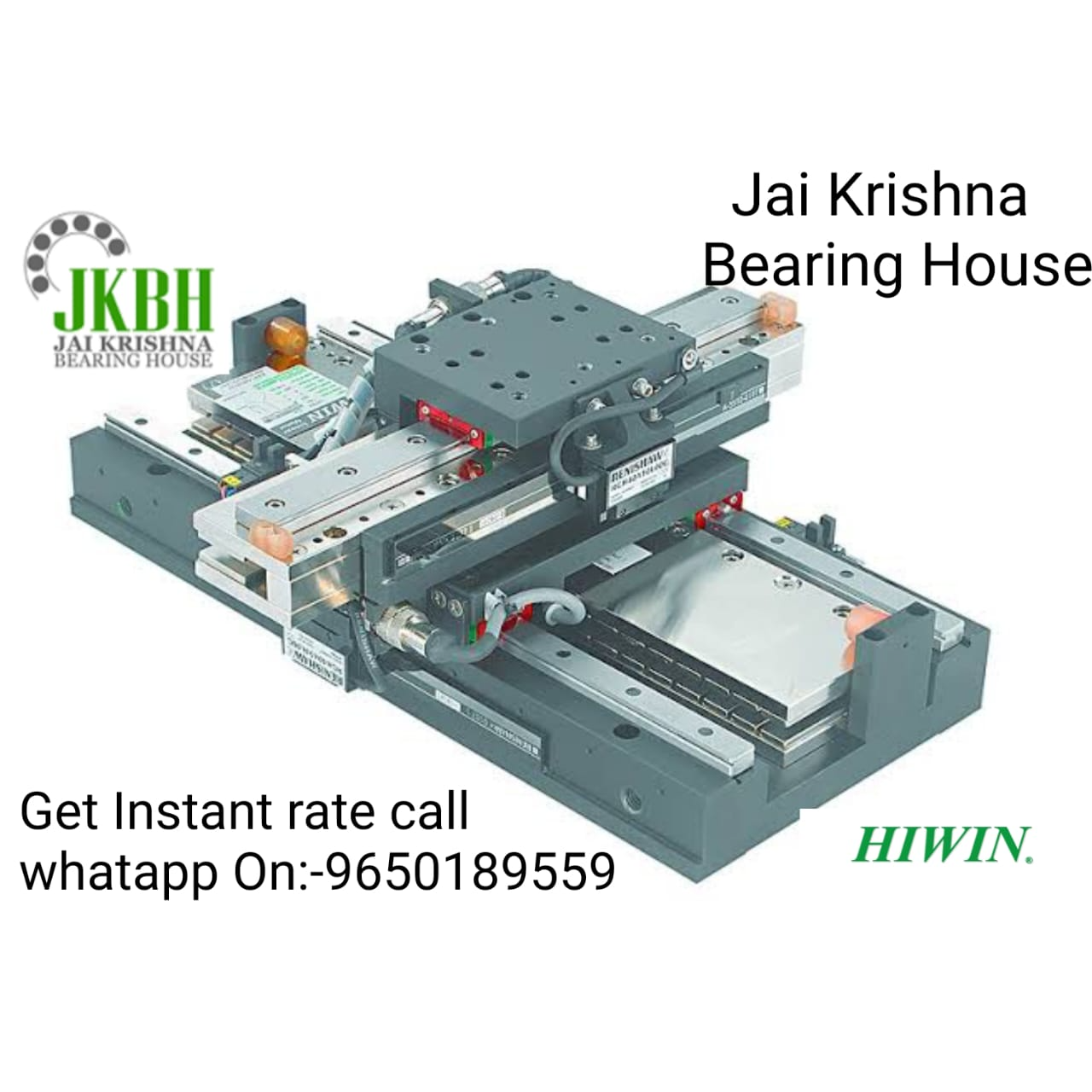

Hiwin Linear Motors: Features, Types, and Applications

Overview of Hiwin Linear Motors

Hiwin linear motors are high-precision, direct-drive motion systems designed to provide smooth, fast, and accurate linear movement without mechanical transmission components like ball screws or belts. These motors are widely used in CNC machining, robotics, semiconductor manufacturing, and automation due to their high speed, zero backlash, and exceptional positioning accuracy.

Key Features of Hiwin Linear Motors

1. Direct-Drive & Zero Backlash

Eliminates the need for ball screws, belts, or gears.

Provides high-speed, ultra-smooth motion with no mechanical wear.

2. High-Speed & Acceleration

Achieves speeds of up to 5 m/s (5000 mm/s).

High dynamic response with rapid acceleration/deceleration.

3. Exceptional Positioning Accuracy

Uses high-resolution linear encoders for sub-micron precision.

Ideal for precision automation and semiconductor applications.

4. Maintenance-Free & Long Lifespan

No mechanical parts mean low wear and minimal maintenance.

Designed for continuous operation in high-performance environments.

5. High Force Output & Efficiency

Provides consistent force with low energy consumption.

Efficient electromagnetic design for optimal power-to-weight ratio.

6. Smooth & Silent Operation

Generates low noise and vibration for stable motion control.

Suitable for cleanroom and high-precision applications.

Types of Hiwin Linear Motors

1. Iron-Core Linear Motors (LMF Series)

✔ High force density for heavy-load applications.

✔ Used in machine tools, CNC machining, and industrial automation.

✔ Provides high acceleration and smooth motion.

2. Ironless Linear Motors (LMS Series)

✔ Zero cogging effect for ultra-precise motion.

✔ Ideal for semiconductor, optical inspection, and medical applications.

✔ High acceleration with low weight and minimal force ripple.

3. U-Shaped Linear Motors (LMU Series)

✔ Designed for compact, high-precision applications.

✔ Offers high acceleration and velocity with minimal heat generation.

✔ Used in robotics, pick-and-place systems, and laser cutting machines.

Applications of Hiwin Linear Motors

1. CNC Machines & Industrial Automation

Provides high-speed and ultra-precise motion for CNC cutting, milling, and grinding.

Used in high-performance machine tools for rapid material processing.

2. Semiconductor & Electronics Industry

Ideal for wafer inspection, PCB assembly, and microchip fabrication.

Ensures vibration-free movement with nanometer precision.

3. Robotics & Pick-and-Place Systems

Enables fast and accurate robotic arms and assembly lines.

Supports AGVs (Automated Guided Vehicles) and automated warehouses.

4. Medical & Laboratory Equipment

Used in MRI scanners, robotic surgery, and pharmaceutical automation.

Provides quiet and vibration-free linear motion for sensitive applications.

5. Laser Cutting & Precision Machining

Used in laser engraving, cutting, and 3D printing machines.

Ensures high-speed positioning with smooth linear movement.

6. Aerospace & Defense

Used in flight simulators, satellite positioning, and missile guidance systems.

Provides reliable motion control in extreme environments.

Why Choose Hiwin Linear Motors?

✔ High Speed & Precision – Delivers ultra-fast motion with nanometer accuracy.

✔ Direct-Drive System – Eliminates backlash and reduces maintenance.

✔ Energy Efficient & Low Heat Generation – Optimized electromagnetic design.

✔ Long Lifespan & Reliability – No mechanical wear, ensuring long-term performance.

✔ Customizable Solutions – Available in various sizes, forces, and configurations.

Keywords

backlash eliminates

sizes forces

extreme environments

pharmaceutical automation

low weight

cogging effect

high acceleration

industrial automation

consistent force

continuous operation

low wear

high speed

automation due

heavyload applications

applications overview

mechanical parts

precision automation

ball screws

ultraprecise motion

ball screws belts

highspeed ultrasmooth motion

ultraprecise motion ideal

highprecision applications types

submicron precision ideal

mechanical transmission components

reliable motion control

vibrationfree linear motion

missile guidance systems

laser engraving cutting

accurate robotic arms

highperformance machine tools

cnc cutting milling

robotics pickandplace systems

minimal heat generation

semiconductor optical inspection

minimal maintenance designed

highresolution linear encoders

accurate linear movement

provide smooth fast