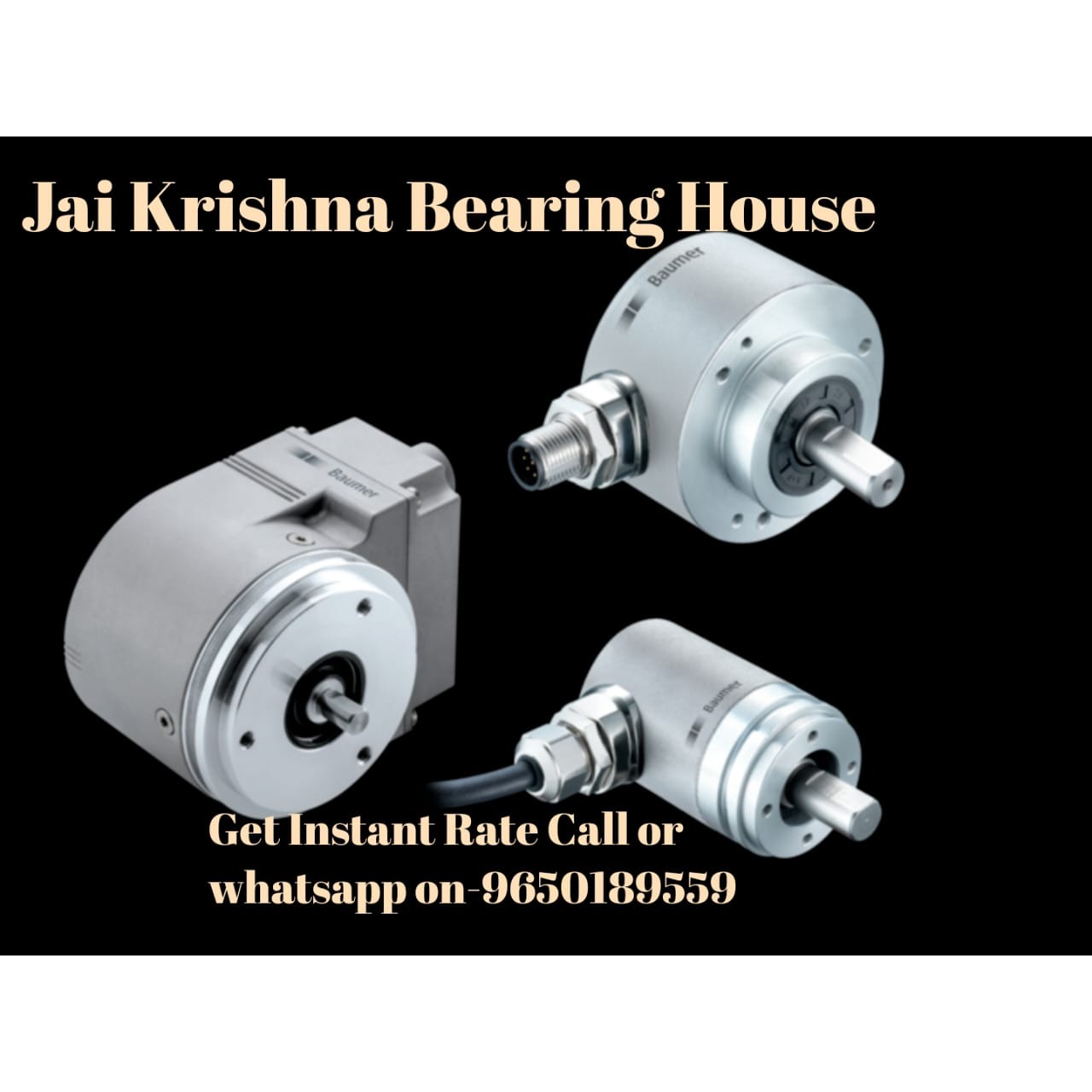

Rotary encoders are essential components in motion control systems, providing accurate position and speed feedback for various applications. Our rotary encoders are designed to meet the rigorous demands of industries such as robotics, manufacturing, automotive, and aerospace. Whether you need an incremental or absolute encoder, our product range delivers the precision and reliability your application requires.

Provide output signals each time the shaft rotates a certain distance.

Ideal for applications requiring precise speed and direction monitoring.

Commonly used in CNC machines, conveyors, and elevators.

Offer unique position values (digital codes) at every shaft angle, ensuring accurate position tracking even after power loss.

Suitable for applications needing exact positioning, like robotic arms and industrial automation.

Our encoders deliver high-resolution feedback, ensuring precise control of motion systems.

Designed to withstand harsh industrial environments, our encoders are resistant to dust, moisture, and vibrations.

Wide Range of Shaft Sizes: Available in multiple shaft sizes and mounting options to fit various mechanical setups.

Versatile Output Options: Support for various output signals, including TTL, HTL, and sine/cosine, ensuring compatibility with a wide range of control systems.

Space-saving designs make our encoders ideal for applications with tight installation constraints.

Applications

Ensure precise control of machinery and equipment, enhancing productivity and efficiency.

Provide accurate position feedback for robotic joints, enabling smooth and precise movements.

Material Handling: Optimize conveyor systems with reliable speed and position feedback.

Essential for systems like anti-lock braking (ABS) and steering, ensuring safe and accurate vehicle control.

Used in wind turbines for monitoring rotor position and speed, contributing to efficient energy generation.

Technological Advancements

Magnetic Sensing Technology: Some of our encoders incorporate magnetic sensors, offering superior durability and resistance to environmental factors.

Optical Sensing Technology: For applications requiring the highest accuracy, our optical encoders provide unparalleled precision.

Customizable Configurations: We offer tailored solutions to meet specific customer requirements, including customized mounting options, output signals, and housing materials.

Why Choose Our Rotary Encoders?

Reliability: Built to perform in the most demanding environments, our encoders are trusted by industry leaders worldwide.

Precision: Achieve unparalleled accuracy with our high-resolution encoders, ensuring optimal performance in every application.

Ease of Integration: With a variety of output signals and mounting options, our encoders integrate seamlessly into existing systems.

Global Support: We provide comprehensive technical support and services to help you get the most out of our products.

Case Studies

Robotics Manufacturing: Learn how our encoders helped a leading robotics company improve the precision of their robotic arms, leading to enhanced productivity and reduced downtime.

Automotive Industry: Discover how our encoders play a critical role in the safety systems of modern vehicles, ensuring reliable operation under all conditions.

Support and Resources

Access a full range of datasheets, manuals, and application notes to support your product selection and integration process.

Our team of experts is available to assist with product selection, customization, and technical inquiries.

Easily download the latest software tools, firmware updates, and product catalogs from our website.

Keywords

full range

Wide Range

power loss

shaft angle

Case Studies

robotic arms

CNC machines

precise speed

critical role

wind turbines

digital codes

product range

Global Support

reliable speed

safety systems

robotic joints

speed feedback

rotor position

motion systems

Rotary encoders

modern vehicles

precise control

optical encoders

product catalogs

firmware updates

existing systems

industry leaders

highest accuracy

conveyor systems

absolute encoder

rigorous demands

magnetic sensors

application notes

product selection

housing materials

anti-lock braking

Material Handling

precise movements

exact positioning

reliable operation

tailored solutions

integration process

Automotive Industry

optimal performance

superior durability

technical inquiries

various applications

Space-saving designs

direction monitoring

essential components

multiple shaft sizes

unparalleled accuracy

environmental factors

industrial automation

latest software tools

unparalleled precision

Robotics Manufacturing

demanding environments

motion control systems

various output signals

unique position values

high-resolution encoders

high-resolution feedback

Versatile Output Options

leading robotics company

accurate vehicle control

various mechanical setups

Technological Advancements

accurate position feedback

accurate position tracking

Optical Sensing Technology

Customizable Configurations

customized mounting options

Magnetic Sensing Technology

efficient energy generation

harsh industrial environments

specific customer requirements

tight installation constraints

comprehensive technical support